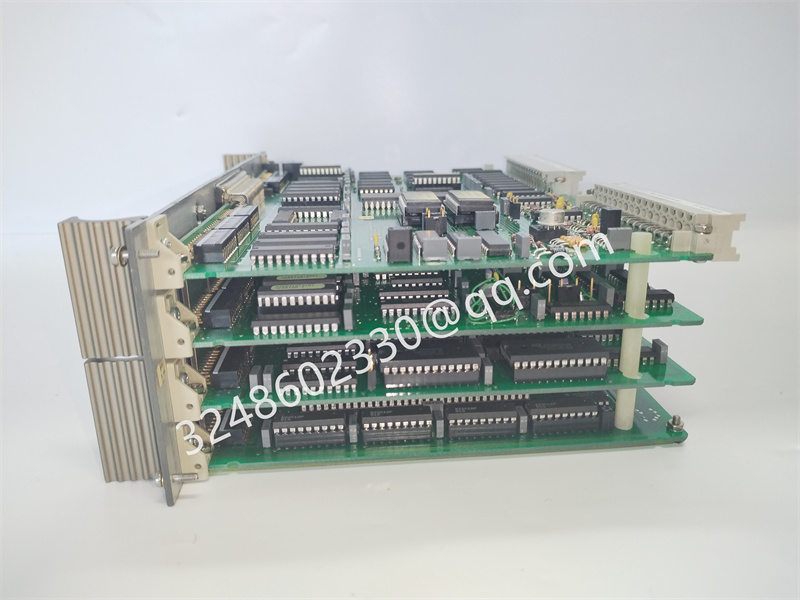

PPA322B HIEE30016R2 HIEE400235R1 Input/Output Controller Module

product description

PPA322B HIEE30016R2 HIEE400235R1 Input/Output Controller Module

1、 Product positioning and core functions

Industrial Automation Control Core

As a key component of ABB’s industrial automation solutions, this module focuses on high-precision data acquisition, real-time monitoring, and complex control logic execution, suitable for industrial scenarios with strict reliability requirements.

Core functions: support multi protocol communication (such as Profibus, Ethernet/IP), edge computing processing, device status self diagnosis and remote management, and realize the whole process automation from simple logic control to complex process optimization.

differentiated advantage

High integration: Integrating data acquisition, transmission, and control functions to reduce system complexity.

Environmental resistant design: high temperature resistance (some models support 486 ℃ environment), anti vibration, suitable for harsh working conditions such as steel and electricity.

Plug and play: Standardized interfaces and modular design shorten deployment cycles and reduce maintenance costs.

2、 Technical parameters and specifications

Detailed specifications of parameter categories

Brand and Model ABB PPA322B HIE300016R2 HIE400235R1

Working voltage 24Vdc/120Vac (some models support 684V high voltage scenarios)

Communication protocols Profibus, Ethernet/IP, Modbus TCP/IP, Bluetooth (some models)

Environmental adaptability, high temperature resistance (486 ℃), vibration resistance, dust and water resistance (IP65 rating)

High performance processor with processing capability and large capacity storage, supporting complex algorithms and real-time data processing

Interface types: Ethernet, serial port, digital/analog input/output (supporting counter attachments)

Physical specifications size 10 × 16 × 23cm (some models), weight 0.81-468kg (specific model needs to be verified)

Certification and international certifications such as CE, UL, ISO 9001, etc

3、 Application industries and scenarios

Heavy industry sector

Steel/Metallurgy: Blast furnace temperature monitoring, rolling mill tension control, energy management system data collection.

Electricity/nuclear power: generator status monitoring, grid frequency regulation, nuclear reactor safety system.

Chemical/Petrochemical: Reactor pressure control, pipeline flow monitoring, automated operation in hazardous areas.

Infrastructure and Manufacturing

Paper/mining: production line speed synchronization, mine ventilation system control, material conveyor belt scheduling.

Intelligent manufacturing: collaborative control of industrial robots, networking of digital factory equipment, predictive maintenance.

Typical Case

A certain steel enterprise has deployed this module to achieve real-time monitoring of blast furnace temperature and linkage with automatic cooling system, reducing manual intervention and lowering the failure rate by 40%.

A certain chemical plant utilizes its multi protocol communication capability to integrate equipment from different brands onto a unified platform, resulting in a 30% increase in operational efficiency.

4、 Technical features and advantages

Stability and reliability

Redundancy design: Supports dual power supply and communication link redundancy to ensure continuous operation.

Self diagnostic function: Real time monitoring of module status, with an accuracy rate of 99% for fault warning.

Flexibility and Scalability

Modular architecture: expandable I/O points, supports hot plugging, and adapts to future capacity upgrades.

Protocol compatibility: Seamless integration with PLC, DCS, SIS and other systems to reduce integration costs.

safety

Data encryption: Supports AES-128 encrypted communication to prevent data tampering.

Access control: Multi level permission management to ensure operational compliance.

5、 Installation and maintenance

Installation Guide

Steps:

Confirm that the power supply and communication lines meet the specifications;

Fix the module to a standard DIN rail;

Complete parameter settings through configuration software (such as ABB Automation Builder);

Perform functional testing and calibration.

Caution: Avoid installation in strong electromagnetic interference environments and ensure good grounding.

Maintenance Strategy

Daily inspection: Monitor module temperature, indicator light status, and communication quality.

Regular maintenance: Clean dust and check wiring tightness every 6 months; Conduct a comprehensive functional test once a year.

Fault handling: Use self diagnostic reports to quickly locate problems, with spare parts replacement time ≤ 30 minutes.

Reviews

There are no reviews yet.