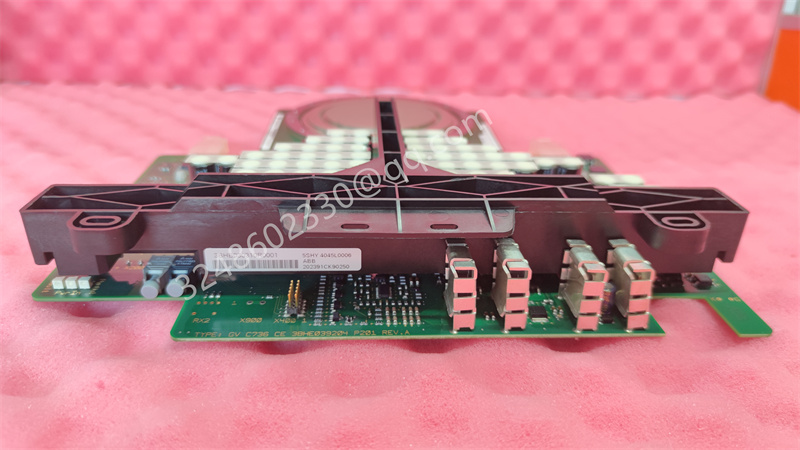

PFV1 401, ID: 3BSE018732R1 Controller

product description

3BSE018732R1 (PFV1 401) Controller

3BSE018732R1 is a controller under the ABB brand that is positioned for industrial automation control scenarios. The “PFV1 401” in its product label is the core specification code for this model of controller, mainly used in medium and high voltage power systems, industrial transmission equipment, or large-scale process control fields, undertaking key tasks such as logic operation, signal processing, and equipment collaborative control.

1、 Core Basic Information

Specific project content

Brand and affiliation: ABB (a globally leading industrial automation and power technology enterprise, this controller belongs to its industrial control product line)

Model identification order number: 3BSE018732R1; Specification code: PFV1 401

Product positioning: High voltage system dedicated controller, focusing on “control accuracy” and “high reliability”, suitable for harsh industrial environments

Typical application scenario 1. Core control of medium and high voltage frequency converters/soft starters;

2. Control of reactive power compensation and harmonic control equipment in the power system;

3. Transmission control logic units for large industrial machinery such as rolling mills, fans, and water pumps

2、 Key technical characteristics

1. Control performance

Multi signal processing capability: supports synchronous acquisition and processing of analog signals (such as current and voltage signals) and digital signals (switch signals), with a high sampling frequency (usually up to kHz level), ensuring real-time monitoring of the status of the controlled equipment.

Logical operations and algorithm support: Built in industrial grade control algorithms (such as PID regulation, logic interlocking, sequence control), customizable control logic according to on-site requirements, and adaptable to dynamic adjustments under complex working conditions.

2. Reliability design

Environmental adaptability: It has a wide temperature working range (usually -25 ℃~+70 ℃) and supports dust and moisture protection design (some scenarios can be equipped with IP20 or above protective enclosures), adapting to harsh environments in industrial sites.

Redundancy and Fault Tolerance: Some configurations support redundant acquisition of critical signals or double checking of control instructions, reducing the risk of system downtime caused by single point failures and meeting the reliability requirements of continuous production scenarios.

3. Communication and compatibility

Communication interface: usually integrated with industrial Ethernet (such as Ethernet/IP, Profinet), serial port (RS485/RS232) or ABB dedicated bus (such as Profibus DP), can communicate with upper computer (such as SCADA system PLC)、 Seamless data exchange between on-site sensors/actuators.

System compatibility: Suitable for ABB’s medium and high voltage transmission systems (such as ACS series frequency converters), process control systems (such as 800xA systems), and can also be compatible with third-party industrial automation equipment through standardized protocols to reduce system integration difficulty.

3、 Installation and usage precautions

Installation environment requirements: It should be installed in a well ventilated, non corrosive gas, and non strong electromagnetic interference control cabinet, avoiding direct contact with high-temperature heat sources (such as power modules), and ensuring that the controller’s operating temperature is stable within the rated range.

Wiring specifications: Strictly follow the wiring diagram in the product manual for the connection of power and signal cables, paying special attention to the shielding treatment of analog signals (it is recommended to use shielded cables with single ended grounding), to prevent signal interference from causing a decrease in control accuracy.

Parameter configuration: The control parameters of the controller (such as PID gain, sampling period, interlock logic) need to be configured through ABB dedicated programming software (such as Control Builder M) or debugging tools. Before configuration, the process requirements of the controlled equipment need to be clearly defined to avoid parameter mismatch and system abnormalities.

Maintenance and Overhaul: Regularly check the power supply voltage and communication link status of the controller. If a fault code appears (which can be viewed through the controller panel indicator light or upper computer alarm information), refer to the troubleshooting manual to locate the problem (such as loose cables, interface faults, parameter errors, etc.), to avoid blind disassembly and hardware damage.

Reviews

There are no reviews yet.