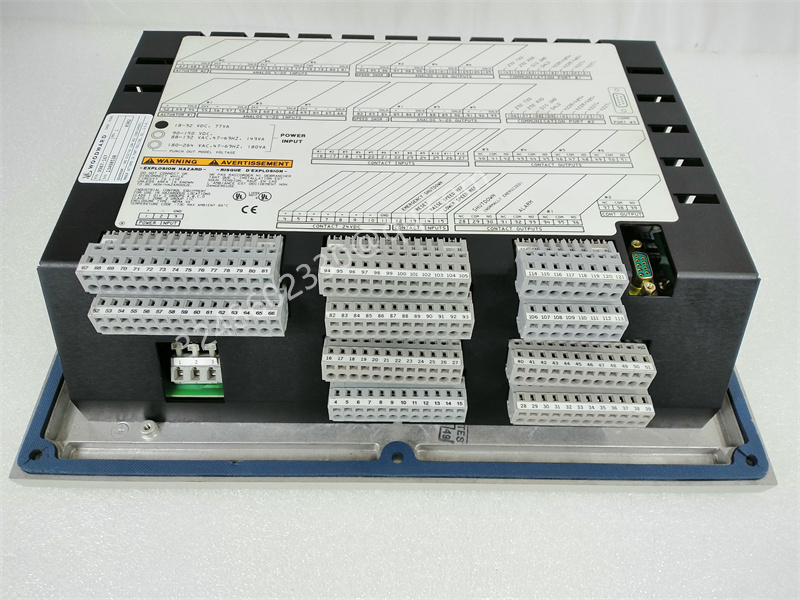

9907-167 WOODWARD servo controller

product description

WOODWARD 9907-167 servo controller

Product Overview:

WOODWARD 9907-167 is a high-performance digital speed controller belonging to the WOODWARD 505E series. It is designed based on a 32-bit microprocessor and is specifically designed for managing the speed, load, and start/stop processes of industrial steam turbines, gas turbines, water turbines, and other equipment.

Main features and advantages

High precision control: adopting advanced PID control algorithm, the speed control accuracy is as high as ± 0.25%, the response time is less than 14 milliseconds, and it can adapt to complex working conditions.

Multiple control modes: Supports isochronous control, Droop control, load sharing, and Isochronous control to meet the needs of different application scenarios.

Automatic start and stop management: equipped with automatic start sequence and critical speed avoidance function, supporting emergency stop protection.

Powerful communication function: supports multiple communication protocols such as MODBUS, PROFIBUS, Ethernet, etc., and can be seamlessly integrated with DCS, PLC, SCADA systems.

Human computer interface friendly: equipped with an 8.4-inch LCD screen, supporting real-time monitoring, historical data recording, and trend analysis.

High reliability design: using industrial grade components, with a wide temperature range design (-40 ° C to+85 ° C), IP67 protection level, and strong electromagnetic interference resistance.

Flexible input/output interface: Supports 4-20 mA current signal or 1-5 V voltage signal input, providing 0-10 V DC analog output or relay output.

smart

technical specifications

Product Model WOODWARD 9907-167

Input voltage 18-36 VDC (isolated)

Analog input 4-20 mA or 1-5 V (programmable)

Digital input with 16 touch points (supports redundancy)

Output signal 0-10 V DC or relay output

Control accuracy ± 0.25%

Response time<14 ms

Communication interfaces RS-485, MODBUS, Ethernet

Working temperature range -40 ° C to+85 ° C

19 inch standard rack installation, depth<20 cm

Weight approximately 15 kg (with protective casing)

Power consumption<15 W

smart

Application scenarios

Power generation and energy: turbine control for thermal power plants, cogeneration systems, and distributed energy.

Industrial manufacturing: speed regulation of rotating machinery (such as compressors and pumps) in the chemical, metallurgical, and papermaking industries.

Ship power: management of engine speed and load for offshore platforms and merchant ships.

Municipal engineering: turbine driven equipment for regional heating systems and sewage treatment facilities.

Related products

9907-149: Suitable for 120 Vac/dc devices.

9907-004: Main synchronizer and load control unit.

9907-1183: Human Computer Interface Module.

9907-838: Suitable for power generator systems and industrial automation.

These products, together with the WOODWARD 9907-167 servo controller, form a complete industrial automation control system suitable for various complex application scenarios.

Reviews

There are no reviews yet.