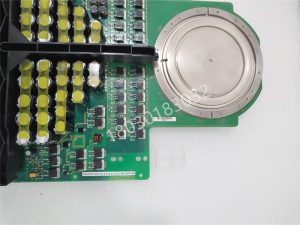

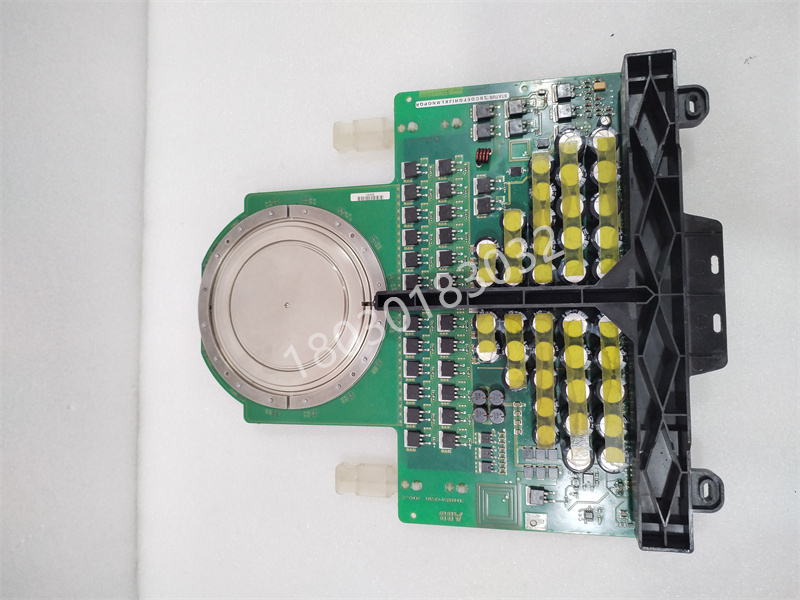

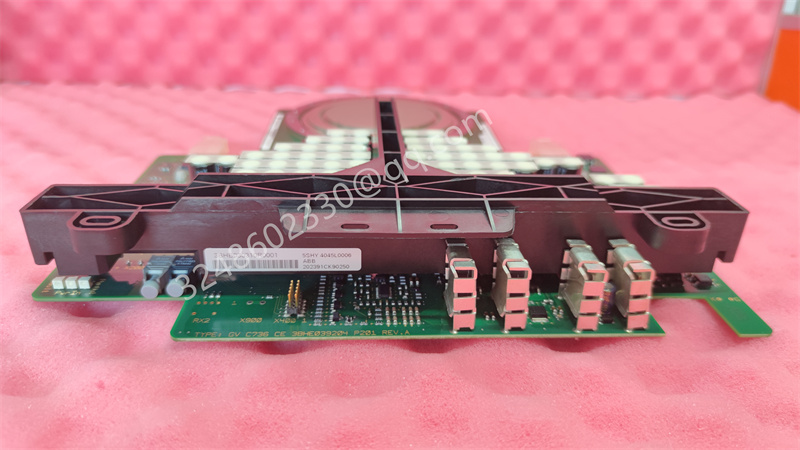

5SHX2645L0004 ABB medium high voltage control board

product description

5SHX2645L0004 ABB medium high voltage control board

1、 Product Definition and Core Positioning

5SHX2645L0004 is a professional control board carefully crafted by ABB for the control needs of medium and high voltage power systems. As the core hub of automation control for medium and high voltage power equipment, it shoulders the responsibility of accurately regulating power parameters, ensuring stable system operation, and implementing complex control logic. In the fields of industrial automation production, power transmission and distribution networks, and large-scale power drive equipment, this control board provides reliable and efficient control solutions for various medium and high voltage power systems with its excellent performance. It is a key component to ensure the safe, stable, and economical operation of power systems.

2、 Core technical characteristics

(1) Powerful electrical performance

Voltage adaptation range: This control board can seamlessly adapt to medium and high voltage levels ranging from 6kV to 35kV, accurately adjust voltage parameters, ensure the stability and reliability of power output, and meet the strict requirements for medium and high voltage power in different industrial scenarios.

Current monitoring and control: With high-precision current monitoring function, it can sense real-time changes in circuit current, accurately monitor and regulate currents up to thousands of amperes, and provide solid guarantees for the safe operation of power systems.

Signal processing capability: Equipped with high-speed signal processing units, it can quickly process various analog and digital signals, with response times as low as microseconds, and can respond promptly to abnormal situations in the power system, achieving rapid protection and control.

(2) Advanced control algorithms

Intelligent PID Control: Integrating advanced proportional integral derivative (PID) control algorithms, it can adjust control parameters in real time according to the system’s operating status, effectively eliminate steady-state errors, enhance the system’s dynamic response capability, and ensure that the power system is always in the optimal operating state.

Fault diagnosis and self recovery: Equipped with intelligent fault diagnosis algorithms, it can quickly identify and locate various faults such as overcurrent, overvoltage, undervoltage, and leakage in the power system. Once a fault is detected, the system will immediately take corresponding protective measures and attempt automatic recovery, greatly improving the system’s fault tolerance and reliability.

Communication and networking functions: Supports multiple communication protocols, such as Modbus, Profibus DP, etc., allowing for convenient data exchange and communication with upper computer control systems or other intelligent devices, achieving remote monitoring, remote debugging, and remote upgrades, meeting the information management needs in industrial automation production.

(3) Reliable hardware design

High specification components: Using high-quality and highly reliable electronic components, all components have undergone strict screening and testing, and can work stably in harsh industrial environments, effectively reducing the failure rate of control boards and extending their service life.

Multi layer PCB design: Using advanced multi-layer printed circuit board (PCB) design technology, the layout and wiring of the circuit board are optimized, signal interference is reduced, and electrical performance and stability are improved. At the same time, the surface of the PCB board has undergone special treatment, providing excellent moisture, dust, and corrosion resistance, making it suitable for complex industrial environments.

Redundancy design: In order to further improve the reliability of the system, the control board adopts redundancy design in key circuit parts, such as redundant power supply, redundant communication interface, etc. When a critical component fails, the redundant part can immediately start working automatically, ensuring uninterrupted operation of the system and avoiding system paralysis caused by a single point of failure.

3、 Typical application scenarios

(1) Industrial motor control

Large fans and pumps are usually driven by medium to high voltage motors in industrial production. The 5SHX2645L0004 control board can accurately adjust the speed and torque of the motor, achieve efficient operation of the motor according to actual working conditions, and effectively reduce energy consumption. At the same time, real-time monitoring and protection of the motor’s operating status can prevent damage to the motor due to overload, stalling, and other faults, improving the reliability and service life of the equipment.

Compressor control: For industrial compressors, this control board can achieve precise control over the start, stop, and operation of the compressor. By optimizing the control strategy, the starting current shock of the compressor can be effectively reduced, mechanical wear can be reduced, and the working efficiency and stability of the compressor can be improved. During the operation of the compressor, the control board can also adjust the working status of the compressor in real time based on parameters such as suction pressure and discharge pressure, ensuring that it is always in the optimal operating condition.

(2) Power transmission and distribution network

Substation automation: In the substation, the 5SHX2645L0004 control board can serve as the core control unit of the substation automation system, achieving centralized monitoring and management of various electrical equipment in the substation. By precise control and monitoring of high-voltage circuit breakers, isolating switches, transformers and other equipment, the safe and stable operation of substations can be ensured, and the reliability and efficiency of power transmission can be improved. At the same time, the control board can also communicate in real-time with the power dispatch center to achieve remote dispatch and control, meeting the needs of smart grid construction.

Reactive power compensation and harmonic control: With the widespread application of power electronic equipment in the industrial field, the problem of reactive power and harmonic pollution in the power system is becoming increasingly serious. This control board can be used in conjunction with reactive power compensation devices, harmonic filters, and other equipment to achieve dynamic compensation of reactive power in the power system and effective control of harmonics. By monitoring real-time parameters such as voltage and current of the power grid, the control board can quickly adjust the output of the reactive power compensation device, improve the power factor of the power grid, and reduce line losses; At the same time, real-time detection and suppression of harmonics in the power grid are carried out to ensure the power quality of the power system.

(3) New energy generation

Wind power converter control: In the wind power generation system, the 5SHX2645L0004 control board is used for controlling the wind power converter. It can accurately control the output voltage, frequency, and phase of the inverter based on environmental parameters such as wind speed and direction, as well as the operating status of the generator, to achieve efficient energy conversion and stable connection between the wind turbine and the power grid. Meanwhile, by protecting and monitoring the inverter, the reliability and operational efficiency of the wind power generation system can be effectively improved, and maintenance costs can be reduced.

Photovoltaic inverter control: For photovoltaic inverters, this control board can achieve precise control of the output voltage and current of the photovoltaic cell array, adjust the working state of the inverter in real time according to environmental factors such as light intensity and temperature, ensure that the photovoltaic inverter is always in the maximum power point tracking (MPPT) state, and improve the power generation efficiency of the photovoltaic power generation system. In addition, the control board also has comprehensive protection functions, which can timely protect the inverter from overcurrent, overvoltage, overheating and other faults during operation, ensuring the safe and stable operation of the photovoltaic system.

4、 Key points for installation and maintenance

(1) Installation process

Installation environment preparation: Choose a dry, ventilated, non corrosive gas, and suitable temperature (-20 ℃ to 50 ℃) installation environment. Ensure that the installation location is away from strong electromagnetic interference sources, such as large motors, welding machines, and other equipment. At the same time, the installation platform should have sufficient strength and stability to support the weight of the control board and related equipment.

Hardware installation: Install the control board in a standard cabinet or control cabinet according to the design requirements, and use matching mounting brackets and screws to fix it, ensuring that the control board is firmly installed and will not loosen due to vibration or collision. During the installation process, attention should be paid to avoiding damage to the components on the surface of the control board.

Wiring connection: Strictly follow the wiring diagram of the control board for wiring operations. The main circuit wiring should use copper core cables that meet the specifications to ensure a secure connection, good contact, and avoid virtual connections or short circuits. Shielded wires should be used for control circuit wiring to reduce signal interference. After the wiring is completed, carefully check the connection status of each wiring terminal to ensure accuracy.

Software configuration and debugging: After completing hardware installation and wiring, it is necessary to configure and debug the software on the control board. According to the actual application scenario, the parameters of the control board can be set through the upper computer software or handheld programmer, such as voltage, current protection threshold, control algorithm parameters, etc. After the setup is completed, perform system debugging to check whether the various functions of the control board are normal and ensure that the system can run stably.

(2) Daily maintenance

Regular inspection: Regularly inspect the control board to check for any signs of damage, deformation, or overheating, loose wiring terminals, and normal operation of the cooling fan. At the same time, professional instruments are used to detect the electrical parameters of the control board, such as voltage, current, power factor, etc., to ensure that all performance indicators of the control board meet the requirements.

Cleaning and maintenance: Regularly clean and maintain the control board, using a clean brush or compressed air to remove dust and debris from the surface and interior of the control board. During the cleaning process, attention should be paid to avoiding damage to the components. For control boards that run for a long time, their heat sinks should also be cleaned regularly to ensure good heat dissipation.

Software upgrade and optimization: With the continuous development of technology and changes in application requirements, ABB will periodically release software upgrade versions for control boards. Users should pay attention to software update information in a timely manner and upgrade the software of the control board according to the actual situation. During the upgrade process, it is necessary to strictly follow the operating instructions to ensure a smooth upgrade process. At the same time, users can optimize the control algorithm of the control board according to actual application situations to improve the performance and efficiency of the system.

Spare parts management: To ensure timely maintenance and replacement in case of control board failure, users should reasonably reserve a certain amount of spare parts, such as commonly used electronic components, vulnerable parts, etc. At the same time, establish a sound spare parts management system to effectively manage the procurement, storage, and use of spare parts, ensuring the quality and availability of spare parts.

5、 Differentiation advantages compared to similar products

(1) Performance advantages

Higher control accuracy: Compared to similar products, the 5SHX2645L0004 control board has significant advantages in voltage and current control accuracy. Its voltage control accuracy can reach ± 0.5%, and current control accuracy can reach ± 1%, which can provide more stable and accurate control for the power system, effectively improving the operational efficiency and reliability of power equipment.

Faster response speed: This control board adopts advanced hardware architecture and high-speed signal processing chips, with signal response time as low as 10 microseconds, far faster than similar products. When abnormal situations occur in the power system, it can quickly respond, take timely protective measures, and effectively reduce fault losses.

Stronger anti-interference ability: By optimizing hardware design and software algorithms, the 5SHX2645L0004 control board has excellent anti-interference ability. In complex industrial electromagnetic environments, it can still operate stably, ensuring the accuracy and reliability of control signals, and reducing the probability of misoperation and failure caused by interference.

(2) Functional advantages

High degree of integration: This control board integrates multiple control and protection functions, such as motor control, reactive power compensation, harmonic control, fault diagnosis, etc., without the need for additional functional modules to meet complex power system control requirements. Compared to similar products with dispersed functions, it greatly simplifies the system design, installation, and debugging process, reducing system costs and maintenance difficulties.

Flexible programming and configuration: The 5SHX2645L0004 control board supports user-defined programming and flexible parameter configuration. Users can freely set and adjust the control logic, algorithm parameters, etc. of the control board through the upper computer software according to their actual application needs, achieving personalized control solutions. This high degree of flexibility enables the control board to better adapt to the needs of different users and application scenarios.

Complete communication and networking functions: In addition to supporting common communication protocols, this control board also has powerful networking functions, which can exchange real-time data with remote monitoring centers or cloud platforms through Ethernet, wireless communication, and other methods. Users can remotely monitor and manage the power system anytime and anywhere through terminal devices such as mobile phones and computers, achieving intelligent operation and maintenance, and improving management efficiency and response speed.

(3) Reliability advantage

High reliability hardware design: Using high-quality components and redundant design, the average time between failures (MTBF) of the 5SHX2645L0004 control board can reach over 50000 hours, far higher than similar products. In harsh industrial environments, it can still maintain stable operation, effectively reducing equipment failure rates and maintenance costs, and improving production continuity and economic benefits.

Advanced fault diagnosis and self recovery function: Compared with similar products, the fault diagnosis algorithm of this control board is more intelligent and accurate, able to quickly locate the fault point and provide detailed fault information. At the same time, its self recovery function is more complete, which can quickly and automatically restore normal operation after troubleshooting, minimizing the impact on production.

Strict quality control and certification: ABB strictly controls the production process of 5SHX2645L0004 control board, from raw material procurement to product assembly and testing, every link follows international standards and specifications. The control board has passed multiple international certifications such as CE and UL, and its product quality and reliability have been widely recognized by users worldwide.

Reviews

There are no reviews yet.