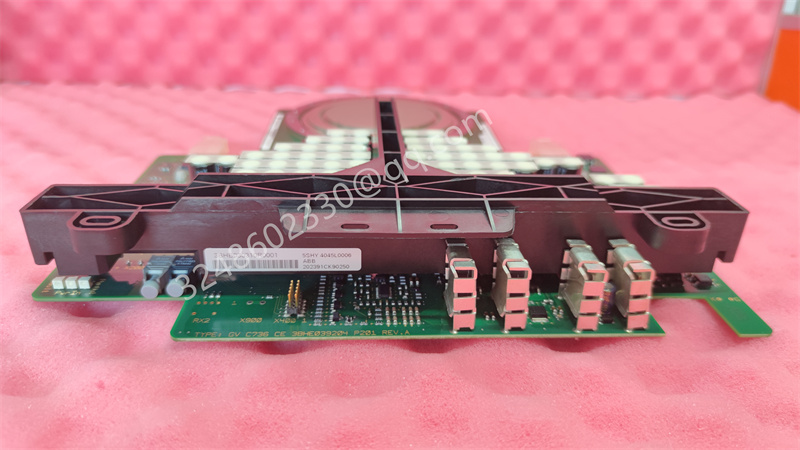

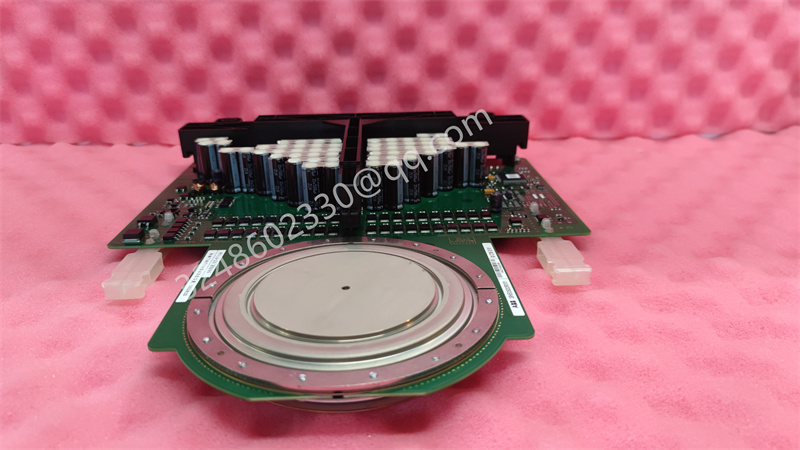

5SHY4045L0004 IGCT thyristor module

product description

5SHY4045L0004 IGCT thyristor module

1、 Product Definition and Positioning

5SHY4045L0004 is a high-performance power module independently developed by ABB based on Integrated Gate Commutated Thyristor (IGCT) technology. As a new type of power electronic device that lies between traditional thyristors and insulated gate bipolar transistors (IGBTs), it combines the high voltage and high current capacity advantages of thyristors with the fast switching characteristics of IGBTs. It can achieve reliable switching without the need to turn off buffer circuits and is widely used in medium to high-power industrial power conversion systems. It is a core device for achieving efficient, compact, and reliable power control, especially suitable for industrial scenarios with dual requirements for switching speed and power density.

2、 Core technical parameter specifications

Electrical performance parameters

Rated on state current (IT (RMS)): 400A, capable of stably carrying continuous current under standard operating conditions, meeting the power requirements of medium power equipment.

Off state repetitive peak voltage (VDRM): 1200V, with high voltage tolerance, suitable for industrial high-voltage power systems.

On state average voltage (VT (AV)): ≤ 1.6V (when IT (AV)=200A), low on state loss, effectively improving system energy efficiency.

Surge current (ITS (50Hz)): 3kA (1 second), capable of withstanding short-term overload current impact, enhancing the system’s anti-interference ability.

Switching characteristics: turn-on time ≤ 3 μ s, turn off time ≤ 5 μ s, switching speed far exceeds traditional thyristors, no need to turn off buffer circuits, simplifying system design.

Gate pole control parameters

Trigger current (IGT): 30-150mA, loose trigger signal requirements, compatible with various gate drive circuits.

Trigger voltage (VGT): 2.5-4.5V, wide range of gate driving voltage, strong compatibility.

Maintain current (IH): ≤ 80mA, ensure stable operation of the device after turning on, and prevent accidental shutdown.

Physical and environmental parameters

Packaging form: SEMITRANS 2 compact package, with a thickness of 32mm, a weight of about 0.6kg, and a power density of 12W/cm ³, saving installation space.

Temperature range: Shell temperature (TC) -40 ℃~125 ℃, junction temperature (TJ) up to 160 ℃, suitable for harsh industrial temperature environments.

Insulation level: Insulation voltage (VIS) 4kV/1 minute, in compliance with IEC 60747 standard, ensuring safe use under high voltage conditions.

Protection performance: It has an IP20 protection level (after installation), effectively preventing dust and foreign objects from entering.

3、 Key technical characteristics and advantages

Integrated gate driver design: IGCT technology integrates the gate driver circuit with the thyristor chip, eliminating the need for complex external turn off buffer circuits. This not only simplifies the system topology, but also reduces parasitic inductance, reduces circuit losses, and improves system reliability.

Balancing high-speed switching and low loss: Compared to traditional thyristors, its switching speed is increased by 3-5 times, which can meet the needs of high-frequency power conversion; At the same time, the on state voltage is low, and the on state loss is reduced by 5% -8% compared to traditional thyristors of the same specification, balancing high speed and efficiency characteristics.

High power density and compact packaging: Adopting SEMITRANS 2 packaging technology, high voltage and high current output can be achieved in a small volume, with a power density of 12W/cm ³, which can significantly reduce the size of power conversion equipment and adapt to industrial scenarios with limited space.

Excellent anti-interference and stability: The combination design of ceramic insulation substrate and metal shell has good thermal conductivity and vibration resistance, and can withstand electromagnetic interference, temperature fluctuations, and mechanical vibrations in industrial environments. The mean time between failures (MTBF) exceeds 50000 hours.

Complete built-in protection mechanism: integrated gate trigger protection, reverse voltage protection, overheating protection, and overcurrent protection functions. When abnormal working conditions are detected, it can quickly respond within 10 μ s, cut off the main circuit or limit the current, avoiding damage to the module and backend equipment.

4、 Typical application industries and scenarios

Industrial variable frequency speed regulation system: As the core component of the inverter bridge in medium and high-power motor variable frequency drives (such as fans, pumps, compressors), it realizes the variable frequency conversion of AC power, improves speed regulation accuracy with high-speed switch characteristics, and reduces equipment energy consumption with low loss characteristics.

New energy power conversion: In photovoltaic inverters and energy storage converters, it is used for bidirectional conversion of DC and AC electricity, adapting to the fluctuating needs of new energy generation. Its high reliability can ensure the stability of grid connected power generation; In wind power converters, they can withstand the current shock caused by the fluctuation of wind turbine speed.

Reactive power compensation in power systems: In Static Var Generator (SVG) and Dynamic Var Compensation Device (SVC), the on/off control of power devices is used to achieve rapid compensation of reactive power, improve the power factor of the power grid, and enhance power quality. The high-speed response characteristics can meet the dynamic compensation needs of the power grid.

Industrial heating equipment: As the core of power regulation in medium frequency induction heating and resistance heating equipment, precise adjustment of heating power is achieved by controlling the triggering phase, which is suitable for temperature control requirements in metal heat treatment, plastic processing and other scenarios.

Rail Transit Traction System: Used for power supply and speed regulation of traction motors in subway and light rail traction converters. Its high power density and anti vibration characteristics can adapt to the harsh operating environment of rail transit.

5、 Installation and maintenance specifications

Installation process and requirements

Preliminary preparation: Confirm that the module model matches the system voltage and current parameters; Clean the heat dissipation base and evenly apply 0.1-0.2mm thick thermal conductive silicone grease to ensure good heat dissipation.

Fixed installation: Using 35mm standard DIN rails or bolts for fixation, the tightening torque is controlled at 5-6N · m to avoid damaging the module packaging due to over tightening or affecting heat dissipation due to over loosening.

Wiring specifications: The main circuit terminals are connected using copper bars or large section cables, and the control terminals are connected using shielded wires. The shielding layer is grounded at one end; Distinguish the wiring between the main circuit and the control circuit to avoid strong electrical interference with the control signal.

Environmental requirements: The installation environment should meet the requirements of temperature -40 ℃~50 ℃, relative humidity ≤ 95% (no condensation), and be away from dust, corrosive gases, and flammable and explosive sources.

Daily maintenance and troubleshooting

Regular inspection: Use an infrared thermometer to measure the temperature of the module casing every month to ensure it does not exceed 125 ℃; Clean the dust on the heat sink every quarter and check the operation status of the cooling fan or water cooling system.

Performance testing: Every six months, the on state voltage and insulation resistance are tested using a multimeter. If the on state voltage deviation exceeds ± 10% or the insulation resistance is below 100M Ω, the module should be replaced in a timely manner.

Troubleshooting: When a malfunction occurs, first disconnect the main power supply and use an oscilloscope to check if the gate trigger signal is normal; If the module is damaged, anti-static measures should be taken during replacement (wearing an anti-static wristband) to avoid static electricity breakdown of the chip.

Long term storage: Store in a dry and ventilated environment with a temperature of 0 ℃~40 ℃ and a relative humidity of ≤ 60%. Conduct an insulation test every six months to prevent moisture from affecting performance.

6、 Supporting products and system solutions

Gate pole drive and control unit: It is recommended to pair it with ABB TCSC series IGCT dedicated trigger board, which can provide accurate gate pole trigger signals and support linkage with PLC and DCS systems to achieve complex control logic.

Cooling system: Suitable for ABB ACS880 series forced air cooling units or water-cooled radiators, temperature feedback cooling control can be configured for high load conditions to ensure that the module operates in the optimal temperature range.

Protection and monitoring equipment: In conjunction with ABB OVR series surge protectors and SPM series power module monitors, real-time monitoring and abnormal protection of module operation status are achieved to enhance system safety.

Overall solution: ABB can provide customized power conversion solutions based on 5SHY4045L0004, covering variable frequency speed regulation systems, reactive power compensation systems, new energy conversion systems, etc., providing full chain technical support from devices to systems.

Reviews

There are no reviews yet.