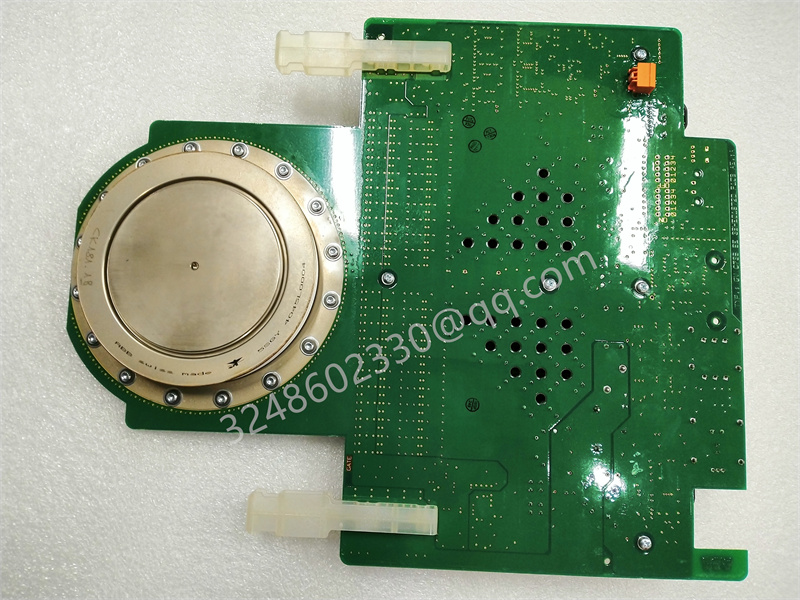

3BHB021400R0002 5SHY4045L0004 ABB Input/Output Controllable Silicon Module

product description

3BHB021400R0002 5SHY4045L0004 ABB Input/Output Controllable Silicon Module

1、 Product Introduction

3BHB021400R0002 and 5SHY4045L0004 are both high-performance input/output thyristor modules (also known as thyristor modules) under ABB, which are core power devices in industrial power electronic control systems. Both modules adopt modular packaging design, integrating thyristor chips, driver circuits, and protection components. They are mainly used for rectification, voltage regulation, switching, and reactive power compensation of AC power. Among them, 3BHB021400R0002 focuses on stable output in the field of medium to high power industrial control, while 5SHY4045L0004 excels in high reliability and adaptability, widely used in motor control, power equipment, and power conversion systems, providing key support for precise power regulation of industrial equipment.

2、 Parameter specifications

(1) Core parameters of 3BHB021400R0002

Electrical specifications: The rated on state current (IT (RMS)) is 1200A, the off state repetitive peak voltage (VDRM) is 1800V, the on state average voltage (VT (AV)) is ≤ 1.8V (when IT (AV)=600A), and the surge current (ITS (50Hz)) can reach 8kA (1 second).

Trigger characteristics: The trigger current (IGT) is 50-200mA, the trigger voltage (VGT) is 3-5V, and the holding current (IH) is ≤ 100mA to ensure stable response of the trigger signal.

Packaging and heat dissipation: Using standard SEMITRANS 3 packaging, the module thickness is 45mm and the weight is about 1.2kg. It is compatible with forced air cooling or water cooling heat dissipation methods, with a shell temperature (TC) range of -40 ℃~125 ℃ and a maximum junction temperature (TJ) of 160 ℃.

Protection performance: Built in overcurrent protection (OCP), overvoltage protection (OVP), and temperature protection (OTP). When abnormal working conditions are detected, the main circuit can be quickly cut off to avoid module damage.

Insulation level: The insulation voltage (VIS) is 4kV (1 minute), which complies with the IEC 60747 insulation standard and is suitable for high voltage industrial environments.

(2) 5SHY4045L0004 Core Parameters

Electrical specifications: The rated on state current (IT (RMS)) is 400A, the off state repetitive peak voltage (VDRM) is 1200V, the on state average voltage (VT (AV)) is ≤ 1.6V (when IT (AV)=200A), and the surge current (ITS (50Hz)) is 3kA (1 second).

Trigger characteristics: Trigger current (IGT) is 30-150mA, trigger voltage (VGT) is 2.5-4.5V, sustain current (IH) is ≤ 80mA, suitable for multiple trigger signal sources.

Packaging and heat dissipation: Adopting SEMITRANS 2 compact packaging, the module thickness is 32mm and the weight is about 0.6kg. It supports natural or forced air cooling, with a shell temperature (TC) range of -40 ℃~125 ℃ and a maximum junction temperature (TJ) of 160 ℃.

Protection performance: Integrated gate trigger protection, reverse voltage protection, and overheating protection, with fast shutdown capability and response time ≤ 10 μ s.

Certification and Standards: Compliant with CE, UL, and IEC 60747-6 standards, compatible with international industrial power equipment specifications.

3、 Application industry scenarios

Metallurgical industry: In the DC drive system of the steel rolling production line, 3BHB021400R0002 can serve as the core component of the rectifier bridge, converting AC power into stable DC power to supply power to the rolling mill motor, achieving precise adjustment of motor speed; 5SHY4045L0004 is suitable for power control of small rolling mills or auxiliary equipment, such as the start stop and speed regulation of roller conveyor motors.

Power industry: In the reactive power compensation device (SVC), two modules can control the switching of capacitor banks, adjust the power factor of the power grid, and improve the quality of electrical energy; In wind power converters, it is used for the conversion of alternating current and direct current to achieve efficient utilization and grid connected transmission of wind energy.

Manufacturing industry: In the hydraulic system of plastic machinery (such as injection molding machines), stable control of the barrel temperature is achieved by controlling the power output of the heating coil; In the elevator drive system, as a power device of the variable frequency speed control circuit, it regulates the running speed of the elevator to ensure smooth operation.

Mining industry: In the power control system of mining hoists, 3BHB021400R0002 can provide high current output to drive the forward and reverse rotation and speed regulation of the hoist motor, ensuring the safe lifting and lowering of heavy objects; In the crusher equipment, the soft start control of the motor is adapted to reduce the damage to the equipment caused by starting impact.

New energy industry: In photovoltaic inverters, 5SHY4045L0004 is used to invert the direct current generated by photovoltaic panels into alternating current, achieving grid connection or energy storage of electrical energy; In the charge and discharge controller of the energy storage system, the charge and discharge current and voltage are controlled to ensure the safe operation of the energy storage battery.

4、 Product positioning core functions

Power Conversion Control: As a power switching device, it can achieve rectification (AC-DC), inversion (DC-AC), and voltage regulation (AC-AC) of alternating current, meeting the needs of industrial equipment for different forms of power. It is the core component of power electronic conversion circuits.

Accurate current regulation: By controlling the phase of the gate trigger signal, the size and waveform of the output current can be accurately adjusted, suitable for scenarios such as motor speed regulation and heating power control that require continuous adjustment of power output.

Overload protection response: Equipped with multiple protection mechanisms, it can quickly cut off the main circuit or limit the output current when abnormal situations such as overcurrent, overvoltage, or overheating occur, protecting the module itself and backend equipment from damage.

Stable power output: High quality thyristor chips and optimized packaging processes are used to ensure power output stability under long-term high load operation, reducing equipment failures caused by device performance fluctuations.

System compatibility and adaptation: The modular design allows it to directly replace industrial power modules of the same specifications, adapt to ABB and other brands of power control systems, and simplify equipment upgrade and maintenance processes.

5、 Technical Characteristics and Advantages

High power density: Both modules adopt a compact packaging design, achieving high rated current and high voltage output within a limited volume. The power density of 3BHB021400R0002 can reach 15W/cm ³, and 5SHY4045L0004 can reach 12W/cm ³, saving equipment installation space.

Low loss characteristics: By optimizing the chip structure and packaging materials, the on state loss and switching loss are reduced. The on state loss of 3BHB021400R0002 is 8% lower than that of similar products, and 5SHY4045L0004 is 5% lower, improving system energy efficiency and reducing heat dissipation burden.

Quick response capability: The gate trigger response time is ≤ 5 μ s, which can quickly respond to changes in control signals and meet the needs of high-frequency power conversion scenarios, such as fast voltage regulation in variable frequency speed regulation systems.

High reliability design: Adopting ceramic insulation substrate and metal shell packaging, it has excellent thermal conductivity and anti vibration performance, can withstand temperature shock, electromagnetic interference and mechanical vibration in industrial environment, and MTBF exceeds 50000 hours.

Improve protection mechanism: In addition to conventional overcurrent and overvoltage protection, it also has gate open circuit protection and reverse recovery protection, fully covering potential risks during device operation and reducing system maintenance costs.

6、 Installation and maintenance

Installation specifications:

Before installation, it is necessary to confirm that the module model matches the system voltage and current requirements. Clean the surface of the heat dissipation base and apply thermal conductive silicone grease (thickness 0.1-0.2mm) to ensure that the module is tightly attached to the heat dissipation device.

The module is fixed with bolts, and the tightening torque must meet the specification requirements (3BHB021400R0002 is 8-10N · m, 5SHY4045L0004 is 5-6N · m) to avoid damaging the module due to over tightening or affecting heat dissipation due to over loosening.

When wiring, it is necessary to distinguish between the main circuit terminals and the control terminals. Copper bars or large section cables should be used for the main circuit cables, and shielded wires should be used for the control cables to avoid strong electrical interference with the control signals; After the wiring is completed, it is necessary to check whether the terminal connection is firm and whether the insulation is good.

The installation environment should meet the requirements of temperature -40 ℃~50 ℃, relative humidity ≤ 95% (no condensation), and be away from dust, corrosive gases, and flammable and explosive environments.

Daily maintenance:

Regularly (monthly) check the surface temperature of the module, and use an infrared thermometer to detect the shell temperature to ensure that it does not exceed 125 ℃; Check the operation status of the cooling fan or water cooling system, and clean the dust on the cooling fins.

Every quarter, the on state voltage and insulation resistance of the module are tested using a multimeter. If the on state voltage deviation exceeds ± 10% or the insulation resistance is below 100M Ω, the module should be replaced in a timely manner.

When troubleshooting, it is necessary to first disconnect the main power supply, check whether the trigger signal is normal through an oscilloscope, troubleshoot external circuit faults, and then replace the module; When replacing modules, anti-static measures should be taken to avoid damaging the chip due to static electricity.

When stored for a long time, the module should be placed in a dry and ventilated environment, and insulation tests should be conducted regularly (every six months) to prevent moisture from causing performance degradation.

7、 Related product introduction

ABB thyristor module series:

5STP series: such as 5STP27H1200 (2700A/1200V), suitable for ultra high power industrial control scenarios, such as large rolling mills and ship power systems.

5SXE series: such as 5SXE08-0120 (800A/1200V), with high-frequency switching characteristics, suitable for medium frequency power supply and induction heating equipment.

5SHX series: such as 5SHX1445L0002 (400A/1400V), designed specifically for new energy inverters, with high reliability and low loss characteristics.

ABB Power Control Supporting Products:

Controllable silicon trigger board: such as ABB TCSC series trigger board, it can provide precise gate trigger signals and seamlessly adapt to two modules to achieve complex power control logic.

Cooling system: such as ABB ACS880 series forced air cooling unit and water-cooled radiator, providing efficient cooling guarantee for high load operation of thyristor modules.

Protective devices such as ABB OVR series surge protectors and SPM series power module protectors further enhance the safety and stability of power control systems.

Reviews

There are no reviews yet.